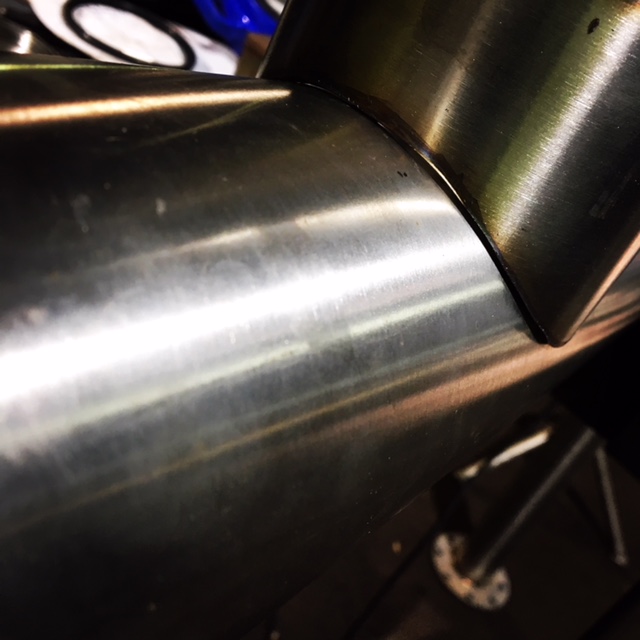

Recently, there has been a lot of hype around the colours that can be produced when welding. It is all over the internet and particularly prominent on social media sites such as Instagram. They look absolutely mesmerising with their incandescent blues, purples, golds and greens. Beyond the eye catching and impressive competition lies a big problem. These colours are putting our stainless-steel work at risk.

There are many things that can change a welds colour such as the type of metal or the gas. The colour can sometimes mean problems but it can also mean nothing at all. The biggest problem we face with colour in our welds is that colour can mean a sign of oxide. Welding with such detail and patience is a skill. When the stainless steel becomes weak and is more susceptible to corrosion because of the weld, then we have an issue. The whole point of using stainless steel is so there is less chance of corrosion thus defeating the purpose.

Deciding on a weld colour depends on your application. It also depends on your metal and your industry. The best idea when welding is to endeavour to end up with a shiny chrome colour. As boring as this may seem, it’s your safest option. It means the weld hasn’t completely compromised the metal. Unless you are an artist and the colours are what you are after.