Dust Collector Systems are used to enhance the quality of the air produced from industrial and commercial processes. They work by removing dust and other impurities from the air to help keep the work site or area safe. Likewise, it can also be used to retrieve valuable solids from being lost to the atmosphere. An effective dust extraction system can be a vital asset in any workshop or factory. A dust collector can also assist in extending working lifespans of machinery as well as the usage and thus quality of work produced.

The significance of a dust collection system for personal safety is also a strong factor in the need for a properly installed, well-running and maintained system. A dust free and clean environment reduces health risks involved with airborne dust. There are 5 different types of dust collectors; this means there are many different options to cater to your specific needs.

Five main types of dust collectors are:

- Inertial separators

- Unit collectors

- Fabric filters

- Electrostatic precipitators

- Wet scrubbers

Inertial separators

Inertial separators use a mixture of forces which include centrifugal, gravitational and inertial to part dust from gas streams. Gravity moves the dust into a hopper, for temporary storage.

There are generally three types of inertial separators, which include:

Baffle Chambers

A fixed plate in the chamber called a baffle plate is placed strategically forcing the air to change direction. Large particles drop out of the air but the air continues to travel through the system. The hopper collects the dust.

Centrifugal Collectors

These collectors separate the dust from a gas stream using cyclonic action. The dust enters the collector on an angle creating a cyclone effect. When the dust hits the walls it then drops and collects in the hopper.

Settling Chambers

A settling chamber is essentially a large box that you can attach into the ductwork. It creates a sudden slow down in the air stream due to the larger volume which allows the particles to settle at the bottom. It requires a lot of space so isn’t common.

Unit Collector

This type of collector manages to control dust at its source. Unit collectors are typically self-contained and small. They are also quite simple in design usually consisting of a fan and a dust collector. They are suitable for operations that offer a limited space and for smaller budgets. It is also appropriate for jobs that are isolated or require relocation.

There are two common types of collectors. The first is a fabric collector and it is used for dust collection where the fine dust particles are present. The second, most common type, is a cyclone collector that is useful when the dust is coarse.

Fabric Filters

Fabric filters are often called bag-houses and use fabric filters to separate dust particles from gas. Various materials can make up the bags. Bag-houses are classified in categories by their method of cleaning:

Shaking

A rod attached to a bag which can be controlled by a motor. This delivers shaking motions to remove built up particles.

Reverse Air

Air flow gives the bag shape. Dirty air flows through the bag from the inside, allowing dust to collect on the inner surface.

Pulse Jet

This type of bag-house cleaning is the most popular. A high-pressure blast of air removes dust from the bag.

Sonic

Sonic is the least common type of cleaning method. The shaking occurs because of sonic vibrations.

Cartridge

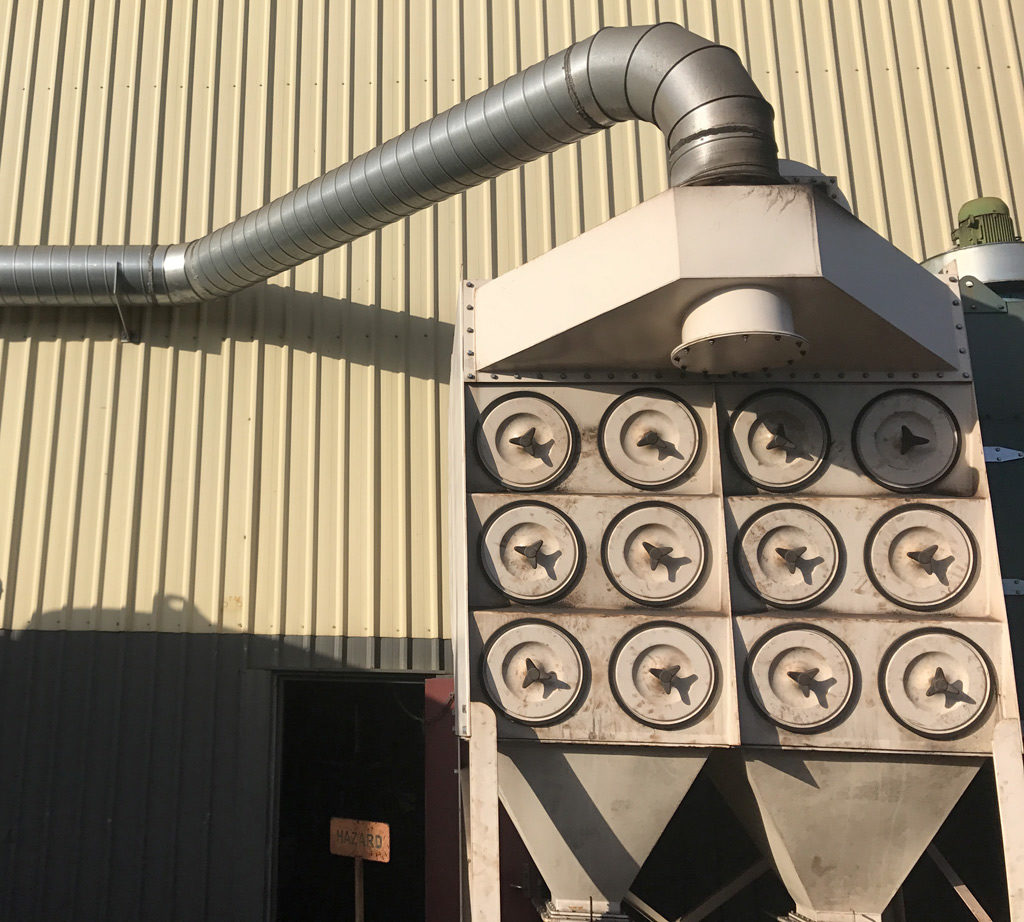

Cartridge collectors use perforated metal cartridges. These contain a pleated, non-woven filter media instead of woven or felt bags used in bag-houses.

Electrostatic Precipitators

Dust particles are separate from gases with the use of electrostatic forces. There are two major types of precipitators which are a high voltage single stage and low voltage two stage. The high voltage option is generally for the mineral processing industry. The low voltage option is normally for air conditioning filter systems.

Wet Scrubbers

This type of dust collection method uses a scrubbing liquid to sieve out fine dust particles. The liquid is often water that will come into contact with gas streams that contain dust particles. There is a huge variety when it comes to wet scrubbers but overall there are 4 basic types:

Low Energy Scrubber

A simple, yet effective method. Water dew forms from spray nozzles and then fall through increasing exhaust gases. Finally, the dirty water is drains from the bottom.

Low-Medium Energy Scrubber

The centrifugal force of the wet cyclone whirls the dust particles and tosses the particulates against the wet collector walls. Water falls from the top of the cyclone against the walls and drains the dust away.

High Energy Scrubbers Co-Current-Flow Scrubber

Referred to as a packed bed scrubber. This type of wet scrubber removes chemicals, acids, fumes, soluble gasses and odours. Dirty gases stream through a specially designed padded agent that is wet from recirculated liquid. The solvent absorbs the air contaminant by chemical or physical means.

High Energy Scrubber

A pressure drop between the back and the front of the scrubber is the result of using turbulence and an absorbent liquid. This creates a motion that thoroughly mixes gas and liquid and filters out the dust.

WDIS specialise in all aspects of Industrial Dust Collector Systems to meet workplace safety and health requirements. We are able to assist with the whole process or just sections depending on your needs. We can provide engineering, manufacturing, supply and installation of fully commissioned systems.

Contact us for a quotation today on 08 9459 3559.